Release Notes 2025-Q2

This document describes the changes in the latest version of SmartTrade for Business Central that is available from the 1st of June 2025 and can be downloaded / updated from Microsoft App Source.

Note

All functionality described in previous release notes still are available unless described otherwise in this document.

Productivity Enhancements

General

Document sorting per user

Functionality added to set up document sorting in list views per user. Options identical to sorting options in page ‘SmartTrade setup’ are available in page 'User Setup'.

Item template expansion

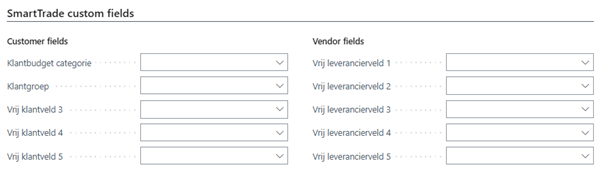

Item templates are now able to save and transfer SmartTrade custom fields to newly created items.

Finance

Item ledger Consumer Unit (CU)

Addition of item ledger entries list page columns showing values per consumer unit. Following columns are added:

-

-

- Costprice per cons.uom (expected).

- Costprice per cons.uom (actual).

- Salesprice per cons.uom.

- Cons. UOM per Base UOM.

- Price./Cons unit. UOM definition.

-

Sales

Automatic Selection of Alternative Shipping Address

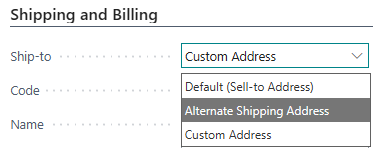

When creating a sales order, selection of ‘alternate shipping address’ in the dropdown of field ‘Ship-to’, will trigger automatically opening a selection window ‘Ship-to Address List’. All delivery addresses are displayed as options insert in the sales order. In case only one shipping address exists for customer, shipping address is selected automatically.

Contact card sales region

The sales region added to contact card will automatically be copied to related customer and related sales orders and sales lines.

Order confirmation to order recipient

Setting added to redirect order confirmation delivery to order recipient instead of billed party, or both. Confirmation used to be sent to invoice address by default.

‘SmartTrade Sales Lines’ showing CU quantity

Added column ‘Cons uom qty.’ containing quantity measured in consumer unit of measure to page ‘SmartTrade Sales Lines’ list view.

Opportunities unit of measurement

Default unit of measurement in opportunities changed to CU.

Supply Chain

Purchasing & Planning

Field ‘Planned shipments’ removed from the purchase blanket order header and is now available on the line level.

Tracking entry item quantity changed by purchase order (PO)

Changing PO line quantity for items with active tracking will automatically have tracking entry quantity changed by PO.

Option to make Expected Receipt Date (ERD) mandatory

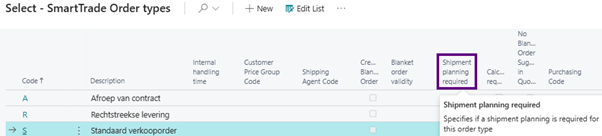

ERD can be made mandatory based on order type. ERD filled at line level is accepted as well. ‘SmartTrade Order Types’ contains a tick box to control this setting.

Posting purchase receipt from transport order

-

-

- Added possibility to post purchase receipts directly from transport orders.

- It is now possible to post separate purchase orders directly from a transport order. Separate line posting is supported as well.

-

Customs clearance file name customization

Page ‘SmartTrade Report Settings’ contains a new settings for configuring how the customs clearance document is named when saved as PDF.

Item lead time substitute when no value

In case an item does not have a lead time value, lead time of vendor card is used. Before this change, 0 was the default substitute if item card lead time field was left blank.

Obsolete field prepared for deletion

Obsolete field 'Planned Shipments' in blanket sales order header is prepared for deletion. This is now arranged on line level. Future update by Microsoft will remove this field entirely.

Vendor/customer information transferred to transport order

Vendor or customer information is transferred to transport orders for easy access.

Production and assembly

Assembly from Purchase Order with Automatic Lot Assignment

When triggering assembly directly from a purchase order, the system now automatically:

-

-

- Creates a lot number.

- Assigns it to the new assembly order, if the item requires item tracking.

-

Assembly order creation from PO card

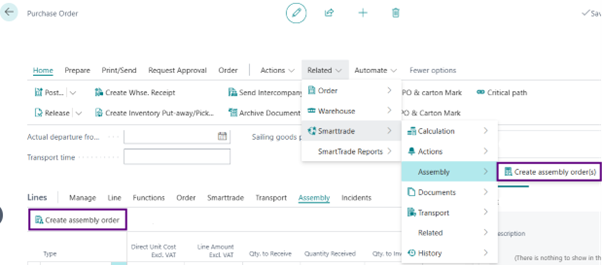

Function added to create an assembly order directly from purchase order. This can be done on line level per item, or it is possible to create multiple assembly orders on header level for multiple items.

Automatic lot number creation for assembly orders

Tracking lines are assigned automatically upon creating assembly order lines. Similar to how item tracking in sales order line creation behaves.

Inventory availability

CU-Based list view

New list view with name ‘SmartTrade Item CU List’ added, displaying quantities in CU. From this view it is possible to enter the item card similar to other list views.

Item list view quantities link to availability

In item list view, quantities of columns ‘Free on inventory’ and ‘Free for sales’ are now designed as links to availability screens. Distinction is made between 2 separate cases:

-

-

- Items with lot tracing: redirection to lot availability.

- Items without lot tracing: redirection to general availability.

-

Item CU list availability displaying Bill of Material (BOM) components

Availability of BOM is added to page ‘SmartTrade Item CU List’. This overview used to display availability of the assembled item, without including availability of related components.

Feature to exclude irrelevant lot availability information

New feature is added providing a cleaner overview of active lot number. Inactive lots are excluded from the list. Activity triggers for being shown in lot availability are purchase, sale or stock among others. Feature can be activated in page Feature Management.

Traceability

Lot Number and Availability Enhancements

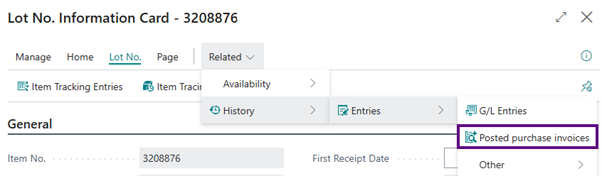

From the lot number card, it is now possible to view all related posted purchase invoice lines.

Lot availability screen displayed information change

Lot availability screen now includes all lots, which includes partially reserved lots. Completely reserved lots were logically excluded from lot availability screen.

Shortcut introduction: ALT+L Lot information list

ALT+L shortcut will respond on several screen to generate an overview of all lotnumbers of selected item. Prerequisite for this function to work is to have an item selected.

Lot status

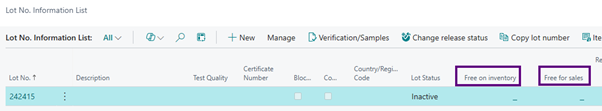

Introduction of lot number status, set to be updated periodically. If no transactions or inventory is available, set status to inactive.

Automatic item lot allocation

If item is set to active lot tracing, lots are automatically generated and assigned.

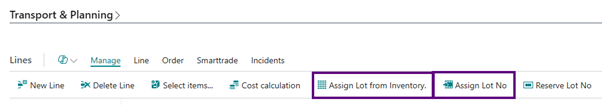

Buttons added to order screens for allocating lots.

Functions added to assign lots from inventory directly from order screens.

Item reservation list showing lot numbers

Changed view from item availability to item lot availability.

Expected receipt date added to lot availability

Availability fields added to Lot No Information List

Fields ‘Free on inventory’ and ‘Free for sales’ are added to item lot list and item card.

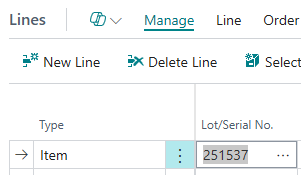

Editable lot number fields in order lines

Field ‘Lot/Serial No.’ is made editable similar to how this works in the sales order line. Changing lots on sales lines automatically results in adjustment of item tracking entries.

CTRL+L shortcut response adjustment

Availability window will not be shown by pressing CTRL+L in case no lot is assigned to the item.

Quality

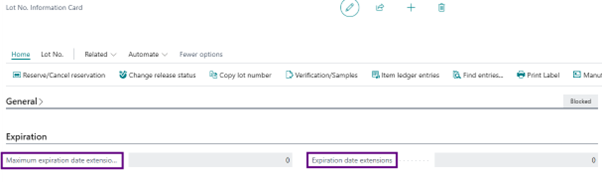

Improvements related to item expiration dates

-

-

- Registration of expiration date extensions.

- Limit to maximum allowed expiration date extensions.

- Expiration date extension counter added and updated on every extension.

-

EDI

Control over EDI on customer level

Customer card contains a switch to direct all orders through EDI, or turn it off entirely.

EDI functional enhancements

-

-

- Changing invoicing method after receipt of EDI message.

- Retrieving EDI messages through job queues.

- Making reservations through EDI.

- Importing messages without EDI lines.

-

EDI technical enhancements

-

-

- IMD Segment: Item description, gross price, and discount are now sent in separate fields within the PRI-AAB segment.

- ORDRSP Handling: If a second release is done on the same order, any unsent earlier ORDRSP message is automatically canceled.

- UNH Segment Correction: Replaces an incorrect envelope number with the expected sequential value.

-

Cost calculation

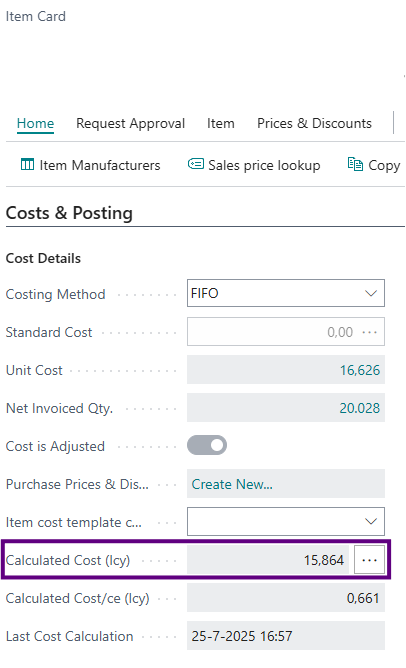

Landed Cost Calculation on Item Card

Added field ‘Calculated Cost (lcy)’ shows the total cost (direct + indirect) for each item, based on:

-

-

- Direct cost: purchase price.

- Indirect cost: Additional charges like duties, freight, from vendor/country-specific cost templates. If no template is found, the system defaults to standard costs. This value is visible on the item card under Fasttab ‘Costs & Posting’

-

Tips

Please check your user settings table to see whether new settings have been added which apply your needs to shield things like cost prices for certain users or prevent users can override planning lines.

Problems solved

General

Report call

Contact code character limit was causing issues when calling for a report related to a customer connected to more than 3 contacts.

Email issue

When emailing a document with more than three contacts specified, an error could potentially occur related to the length of a filter.

Supply Chain

Supply Chain related corrections

-

-

- Issue with manual planning entries in blanket purchase orders.

- Error occurring when a new transport order is added to a purchase order.

- Fixed error when creating a new purchase order.

- Call-off from blanket order did not completely update order lines.

-

Production and assembly

Master data status and assembly order components

Master data status setting ‘Assembly Orders Allowed’ did not prevent items being added to assembly orders as components.

Inventory availability

Alignment of location settings with Factbox item availability

If the option ‘Hide in availability’ is set to active, this information is now hidden from Factboxes as well.

Show availability per event.

Correction applied for availability per event, filter settings from the sales side were obstructing visibility of items purchased and in transit.

Traceability

Tracing line automatic alignment with order line

Fix applied for error upon changing order line quantity of item with active lot tracing. Line on tracing will be changed automatically along with order line quantity.

Lot related corrections

-

-

- Removal of old entries when changing lot on transfer order.

- Wrong window being opened from lot availability being accessed from demand forecast.

- Lot number tracking entry not being cleared upon posting partial deliveries.

- Malfunctioning lot assignment. Lot number line was not populated in response to change made in BC26 update.

- Malfunction of automatically added tracking lines when lot is selected on assembly.

- Updated availability calculation to prevent errors in case of blanket orders combined with forecasting lines.

- Lot availability showing wrong assembly quantity.

- Broken filter on lot number in lot availability screen.

- Missing field for lot on posted assemblies and lines.

- Lot availability not including sales reservations of items in transit on transfer orders.

- Incorrect amount of ledger entries when lot number was added to a transfer line.

-

Quality

Expiration date check corrected.

Expiration date was checked when ‘. ‘Use Expiration Dates’ in the ‘Misc.´ section of screen ‘Item Tracking Codes’.

EDI

EDI related corrections

-

-

- Delivery date was not passed through correctly from EDI to Sales orders.

- EDI cleaning routine filtered incorrect, resulting in less effective cleaning procedure.

- Loosened unnecessarily strict EDI-check.

- Passing on of ORDERRSP from EDI order to EDI sender.

- Error in EDI UNH segment content.

- Fixed lead time transfer from EDI message to order.

- Batch import of multiple EDI message.

- When assigning a single lot number, the lot number was not populated on the sales order line.

-

Recommended links

©HB Software B.V.